Oyster Spa Pool - Continuity For Seafood Lovers

A happy co-incidence by researchers at a North Auckland marine company may have saved oyster lovers from losing their favourite delicacy, with a treatment as easy as giving the young oysters a dip in their ‘spa pool’.

The toxic bloom that severely affected the mussel industry looked set to do the same for oysters until some lateral thinking saved the day. Mussel and oyster growers, Biomarine, found the answer while researching ways of heat treating oyster shells to kill any external organisms, while keeping the oysters alive and in peak condition for export to Australia.

Biomarine’s Jim Dollimore explains: “we completed our heat treating trials with Crop & Food Research in April last year and then the toxic bloom hit in June. We thought there might be some cross over in the technology; if we could kill anything on the outside of the shell without killing the oyster, maybe we could use that technique to kill the Gymnodinium catenatum cysts causing toxic bloom.”

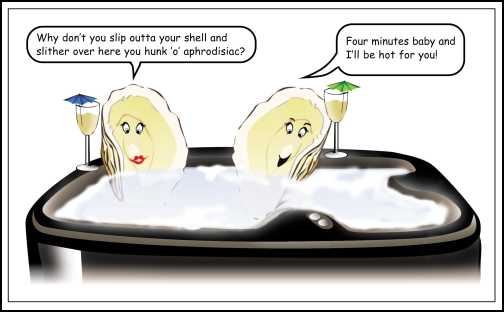

The result meant that all oyster ‘sticks’ containing young spat from the Kaipara Harbour are treated to a stint in a specially designed giant spa pool for oysters – a 3.5 tonne water bath with gas burners heating the water to a precise 50 degrees centigrade for the four minute ‘spa.’

“It’s important that all oyster spat go through the treatment to keep control over toxic bloom,” says Mr Dollimore. “Nearly all the spat for New Zealand’s oyster farms come from the Kaipara harbour and the consequences for the industry were disastrous if we weren’t able to develop a long term solution quickly. We could have lost 90% of the industry. We were just lucky we were doing it at the right time.”

Mr Dollimore says the technique developed for the Oyster Farmers Association now has Ministry of Fisheries endorsement so all spat must be treated before being dispersed to farms around the country.

Mr Dollimore says the transition of basic research from one application to an industry-wide issue was a happy co-incidence. “The Foundation for Research, Science and Technology helped the initial research with $30,000 of funding through Technology New Zealand’s Technology for Business Growth and it was that research which was the platform for this next step,” he says.

Mr Dollimore says all the elements were ideal for using heat treatment. “ Oysters grow exposed to the sun, so they can cope well with high external temperatures, whereas the catenatum cysts stay in the water. We knew we could heat oysters for a specific period of time and totally kill the bugs but not damage the oysters at all”

Ian Gray, investment manager at the Foundation for Research, Science and Technology, which provided funding for the early research, says “We are pleased to support research which benefits the wider industry sector. Biomarine has a strong record of R&D and are an excellent example of a company adding value to its processes through technology and innovation.”

-ends-

Trademe: Trash To Treasure - Kiwi Make The Most Of Unwanted Christmas Gifts

Trademe: Trash To Treasure - Kiwi Make The Most Of Unwanted Christmas Gifts  Financial Markets Authority: FMA Seeks Clarity From High Court On Use Of Eligible Investor Certificates In Wholesale Investment Sector

Financial Markets Authority: FMA Seeks Clarity From High Court On Use Of Eligible Investor Certificates In Wholesale Investment Sector Scion: Scion’s Novel Internship Model Connects Talent With Industry

Scion: Scion’s Novel Internship Model Connects Talent With Industry Financial Markets Authority: Westpac Admits To Misleading Representations That Resulted In $6.35m In Overcharges

Financial Markets Authority: Westpac Admits To Misleading Representations That Resulted In $6.35m In Overcharges Bill Bennett: Download Weekly - Review Of 2024

Bill Bennett: Download Weekly - Review Of 2024 Bill Bennett: One NZ scores worldwide first as Starlink direct-to-mobile launches

Bill Bennett: One NZ scores worldwide first as Starlink direct-to-mobile launches