SDK & Microwave Chemical Start Development Of Chemical Recycling Technology To Transform Plastic Into Chemical Feedstock

Showa Denko (SDK) (Tokyo: 4004) and Microwave Chemical Co., Ltd. (Microwave Chemical) have started joint development of a new microwave-based chemical recycling technology to directly transform used plastic into basic chemical feedstock. The two companies are implementing various steps to achieve carbon neutrality by 2050, and aim to commercialize the new technology soon.

SDK and Microwave Chemical will aim to develop a technology that decomposes used plastic containers and packaging by irradiating microwave, thereby producing basic chemical feedstock such as ethylene and propylene. By the end of this year, the two companies will study conditions for formation of product through microwave heating, search for catalysts to improve the yield of targeted components, and try to optimize conditions and processes for decomposition to establish basic technology.

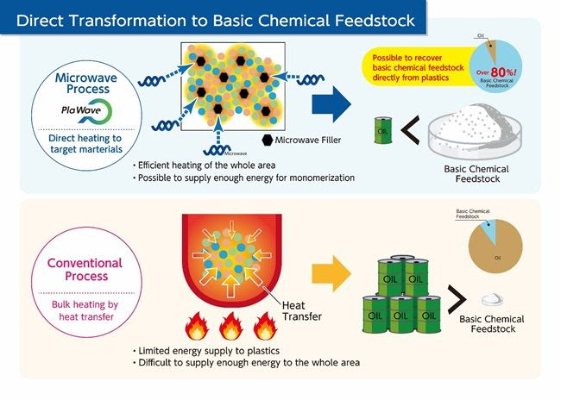

In the joint technology development, the two companies will use microwave heating, a kind of electric heating used also in a microwave oven. When an object is irradiated, microwave directly affects dielectric material, resulting in internal heating, selective heating and rapid rise in temperature. Compared with other heating methods, microwave heating is special in that it heats only the object. In the planned process, we will use microwave absorber (filler) to give energy in a focused way to used plastic, enabling efficient decomposition of used plastic into basic chemical feedstock. It will also reduce energy consumption for decomposition compared with conventional methods. (Chart 1) Taking advantage of such characteristics of microwave heating, we will aim to transform used plastic directly into basic chemical feedstock with low energy consumption and high efficiency.

SDK has been engaged in chemical recycling operations since 2003 at its Kawasaki Plant, producing clean hydrogen and ammonia through thermal decomposition of used plastic. As a result, SDK has accumulated overall know-how concerning procurement of raw materials, decomposition, and manufacture of final product. (Chart 2) With its high-level technologies and deep expertise in process development, Microwave Chemical has the capability to scale up microwave technologies. In the area of chemical recycling, the company has established "PlaWave(TM)," a platform of microwave-based plastic decomposition technology, thereby dealing with various types of plastic.

SDK and Microwave Chemical will work together to contribute toward achieving resource saving, resource circulation and a carbon-neutral society through this joint development.

Vegetables New Zealand: Asparagus Season In Full Flight: Get It While You Still Can

Vegetables New Zealand: Asparagus Season In Full Flight: Get It While You Still Can  Bill Bennett: Download Weekly - How would NZ telecoms cope with another cyclone

Bill Bennett: Download Weekly - How would NZ telecoms cope with another cyclone NZ On Air: Firm Audience Favourites Lead NZ On Air Non-Fiction Funding

NZ On Air: Firm Audience Favourites Lead NZ On Air Non-Fiction Funding Insurance and Financial Services Ombudsman: Woman Gets $40k More After Disputing Insurer’s Decision

Insurance and Financial Services Ombudsman: Woman Gets $40k More After Disputing Insurer’s Decision BNZ: A Quarter Of Older NZers Fear Going Online Due To Scam Concerns

BNZ: A Quarter Of Older NZers Fear Going Online Due To Scam Concerns University of Auckland: Scientists Develop Tool To Monitor Coastal Erosion In Fine Detail

University of Auckland: Scientists Develop Tool To Monitor Coastal Erosion In Fine Detail