Managing Risk Around Hand-arm Vibration

Vibration from tools and machines can be transmitted into workers’ hands and arms. Workers can be permanently harmed if they regularly and frequently use hand-held power tools and machines, especially for long periods of time.

Workers can develop hand-arm vibration syndrome (HAVS) or carpal tunnel syndrome (CTS) if they regularly and frequently use hand-held power tools and machines, especially for long periods of time.

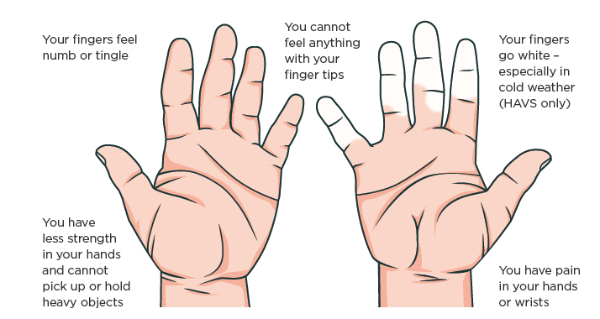

What are symptoms of HAVS and CTS?

The symptoms can come and go, but with continued exposure to HAV, symptoms can become prolonged or permanent. This could happen after only a few months of exposure, but in most cases it will take a few years.

As a result, workers could experience pain, distress and disturbed sleep.

HAV could also make existing hand injuries or illnesses workers have worse.

People who are exposed to noise and vibration at the same time are more likely to lose their hearing than people who are exposed to noise alone.

If the symptoms are ignored, the damage can become permanent and disabling. As a result, workers may not be able to do simple tasks like opening jars or using a phone. Workers may have to stop working with vibrating equipment if they can no longer safety handle tools/machines.

How can you work out if exposure to HAV is something you need to deal with?

Different power tools and machines produce different amounts of vibration. Power tools and machines that are older or not well-maintained usually vibrate more.

The use of power tools and machines – typically high vibration ones – is linked to HAVS and CTS. These include using hand-held or hand-guided tools like:

- chainsaws

- jackhammers/demolition hammers/demolition breakers

- hammer drills

- jigsaws

- sanders

- hand-held grinders

- weed whackers/line trimmers

- powered sanders

- pneumatic drills

- powered lawn mowers.

HAVS and CTS are seen in industries such as forestry, metal working, demolition, road repair, construction, heavy engineering and foundries.

There are many factors that can influence the effects of exposure to HAV. These include:

- the condition of the power tool/machine

- the vibration intensity

- the duration of exposure (time/day, frequency)

- the temperature the work is being carried out in

- operator technique (for example, how hard the worker grips the power tool/machine)

- operator health and medical history (including if they smoke).

To work out whether your workers are at risk, think about:

- the power tool/machine

- how the work is organised

- the task

- your workers.

There is a recommended maximum daily amount of HAV that workers should not exceed.

- We recommend that workers have a maximum daily exposure limit of 5m/s2 (8 hour average).

- We expect you to put control measures in place if your workers are exposed to ‘the exposure action value’ of 2.5m/s2 (8 hour average) or more.

The power tool/machine

- What is the vibration

level of the power tool/machine?

See the manufacturer’s user manual or specification. - Is the power tool/machine

regularly maintained?

There is greater vibration when power tools and machines are not well maintained.

Blunt tools mean tasks take longer, meaning more exposure to vibration. - Is it a heavy

hand-held power tool/machine?

Tighter grip is needed for heavier power tools and machines. Gripping too tightly increases the chances of developing HAVS or CTS. - Does a large area of the hand contact

the power tool/machine?

The larger the areas of contact, the more vibration workers are exposed to. - Does it have a well-insulated

handle?

Poorly insulated handles mean workers are exposed to more vibration.

The task

- Is the power tool/machine the right

one for the task?

Using the wrong power tool/machine can mean work takes longer, increasing exposure to vibration.

Using over-powered tools expose workers to higher levels of vibration. - What is the

vibration level for the task and how long does the task

take?

See the manufacturer’s user manual or specification for vibration data. The higher the vibration, the greater the risk. - What is the hardness

of the material the power tool/machine will contact (for

example, is it concrete, is it wood, is it soft

soil)?

The harder the material, the more vibration. - Does the task involve workers

lifting power tools overhead or other awkward

postures?

Tighter grip is needed for awkward postures. Gripping too tightly increases the chances of developing HAVS or CTS.

How the work is organised

- How long are your workers

exposed to the vibration?

How many hours within the shift involve operating the power tool/machinery?

How often do your workers take breaks?

How long are they exposed to high levels of HAV versus lower levels?

How often do they operate the power tool/machine? Every day?

The longer workers are exposed to vibration, the more chance of developing HAVS or CTS. - Is

the work in cold environments?

Cold increases the chances of developing HAVS or CTS.

Your workers

- Do your workers always use the

right power tool/machine for the job?

Using the wrong power tool/machine can mean work takes longer, increasing exposure to vibration. - Have they

been trained how to properly use the power tool/machine? Do

they have poor technique (awkward postures) or grip the

power tool/machine more tightly than

needed?

Gripping more tightly than needed increases the chances of developing HAVS or CTS. - Are they being exposed to HAV above the

recommended levels?

The Health and Safety Executive (UK) has tools to help work out whether workers could be being exposed to HAV exceeding the exposure action value (2.5m/s2 (8 hour average)). These tools are: - the ready reckoner: www.hse.gov.uk

- the vibration calculator: www.hse.gov.uk

- Have workers previously reported symptoms of HAVS or CTS? Have you asked workers recently if they are having any early signs?

- Do they

smoke?

Smoking decreases blood circulation and increases the chance of HAVS. - How is their

general health?

Medical conditions such as diabetes and arthritis, and injuries such as frostbite increases the chances of developing HAVS or CTS.

How can you manage the health and safety risks from HAV?

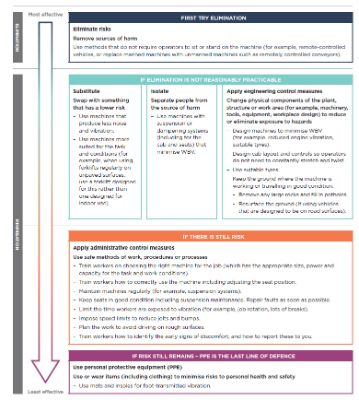

You must first try to eliminate a risk so far as is reasonably practicable.

If it is not reasonably practicable to eliminate the risk, it must be minimised so far as is reasonably practicable.

If you need to manage the risks from HAV, you could:

- reduce the amount of vibration workers are exposed to

- reduce the time workers are exposed to vibration (over each shift, over the time they work for you)

You can use the hierarchy of control measures to help you to work out the most effective control measures to use.

Control measures should remain effective, and be fit-for-purpose, suitable for the nature and duration of the work, and used correctly.

With your workers, regularly monitor and review control measures to confirm that the measures are effective.

However you should immediately investigate, and review your control measures when:

- the control measure does not control the risk, or

- a new hazard or risk is identified, or

- workers report symptoms of HAVS and CTS to you, or

- you receive exposure monitoring or health monitoring results that show your workers are being harmed or at risk from HAV (Section 4), or

- there will be a change in the workplace or work (for example, new equipment, new or changed work processes, increased workload, extended hours or additional/changed shifts), or

- your workers or their representatives indicate a review is necessary or request it.

Use the results of these reviews to continually improve how you manage health risks.

Tourism New Zealand: Tourism New Zealand Invites The World To Find Their 100% Pure New Zealand In New Global Campaign

Tourism New Zealand: Tourism New Zealand Invites The World To Find Their 100% Pure New Zealand In New Global Campaign Bill Bennett: Comcom warns 2degrees over satellite marketing

Bill Bennett: Comcom warns 2degrees over satellite marketing Transpower: Major Electricity Development For Western Bay Of Plenty A Step Closer

Transpower: Major Electricity Development For Western Bay Of Plenty A Step Closer Alcohol Beverages Council: Turning The Tide - New Zealanders Unite To Curb Harmful Drinking

Alcohol Beverages Council: Turning The Tide - New Zealanders Unite To Curb Harmful Drinking University of Auckland Business School: Economists Urge Action To Prevent ‘AI Poverty Traps’

University of Auckland Business School: Economists Urge Action To Prevent ‘AI Poverty Traps’ Bill Bennett: Australian warship takes rural fixed wireless broadband offline

Bill Bennett: Australian warship takes rural fixed wireless broadband offline